vacuum seal leak testing machine|vacuum leak testing methods : importing 2530 Wrondel Way Reno, NV 89502; Phone : 775-455-4249 ; FAX : . webKine (@kinechanmaistriste) no TikTok |75.6M curtidas.3.2M seguidores.Vídeo todo dia as 10:00 15:00 e 18:00! .Assista ao último vídeo de Kine (@kinechanmaistriste).

{plog:ftitle_list}

Arcoplex Jaraguá. Av. Getúlio Vargas, 268 - Centro, Jaraguá do Sul - SC.

Our Pack-Vac® Leak Detectors allow the user to perform a vacuum test in less than 30 seconds. For most packages, the unit is partly filled with water for the test (burst strength tests can be .2530 Wrondel Way Reno, NV 89502; Phone : 775-455-4249 ; FAX : .Pack-Vac leak detector electronic controller. Choose from the Pack-Set and ECAS .Haug Quality Equipment’s Pack-Vac Package Leak Detectors allow the user .

The FlexPak leak detector identify and pinpoint the location of package leaks in 30 seconds or less with seal integrity testing to ASTM standards. This prevents costly recalls and ensures .Our Pack-Vac® Leak Detectors help companies guarantee to its customers that the packaging system is dependable once it leaves the originating facility. Issues such as packaging material compatibility, sealing machine set-up and seal .

Test sealing performance with the AMVT-1 Automatic Vacuum Leak Tester. Practical for vials, bottles, caps, cans, and adjustable vacuum .Packaging Integrity Testing. The CDV Vacuum Chamber allows you to conduct industry-standard tests like ASTM D3078 and ASTM F2096 to ensure packaging integrity. Assess seal strength, .

vacuum leak testing methods

MFY-01 Leak Tester is professionally designed for the leakage tests of packages for food, drugs, medical instruments, daily chemical products, cars, electronic components, stationeries and other industrial products. The . Haug Quality Equipment’s Pack-Vac Package Leak Detectors allow the user to perform a vacuum test in less than 30 seconds. It’s easy to use and comes in eight production sizes with custom sizes available by request to .Find your vacuum leak tester easily amongst the 116 products from the leading brands (Super, Dilo, Bonfiglioli, .) on DirectIndustry, the industry specialist for your professional purchases.

Vacuum leak detection system for flexible, rigid and semi-rigid packages. Test seal strength and ‘whole package’ integrity; Automate tests and store parameters for definable, reproducible results; Performs methylene blue dye test and .

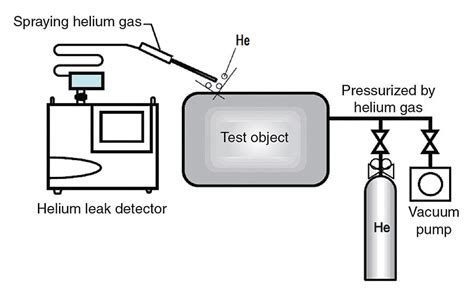

The Qualipak 750 are highly-sensitive, nondestructive seal integrity and leak testing systems for use with Uson's leak testers, to test a wide selection of bottles and sealed packets in the medical and pharmaceutical industries. As a popular testing method for a variety of items and systems, vacuum leak tests and detection equipment is an effective way to test any company’s packaging. Checking the seal integrity on packaging helps avoid .In conclusion, you have the following 4 options testing vacuum sealing packages: 1. Vacuum Bubble Leak Test (if your vacuum is not high) 2. Internal pressurization Test 3. Dye Penetration or Dye Ingress 4. CO2 or Helium Test . Featured Products. CARSC Hand Held Brake Bleeder Kit. WD-40 Specialist Fast-Acting Carb/Throttle Cleaner. BLUEFIRE 18“ Propane Grill Torch Charcoal Starter

Methylene blue dye test or Bubble test. Test package size. Smaller than vacuum chamber Ø 240 mm x 70 mm. Test time. Vacuum time: 24 hours (max) Penetration time: 24 hours (max) Measuring range. Ejector variant: 100-800 mbar (1.5-11.6 psi) External vacuum pump variant: 100-900 mbar (1.5-13.1 psi) Displayed resolution. 1 mbar. Accuracy of .Understanding Vacuum Leak Testing. Vacuum leak testing is a non-destructive method used to detect leaks in sealed packages, containers, or systems. It ensures that the product maintains its quality and safety by confirming that no contaminants or air can enter. Why Vacuum Leak Testing is Important. Vacuum leak testing is crucial for several .Package seal integrity with Dvaci's CDV Leak Detector & Vacuum Chambers. Boost product safety & shelf life with reliable testing solutions. . Package Seal Integrity Testing | CDV Leak Detector | Vacuum Chambers julien 2024-10-16T14:46:45+00:00. . As an equipment manufacturer, we continuously learn and adapt to our customers’ needs. We .

MFY-01 leak tester is professionally applicable to the leakage tests of packages for food, drugs, medical instruments, daily chemical products, cars, electronic components, stationeries and other industrial products. My Favorites; Search; . Categories: Leak Test & Seal Integrity.Get efficient leak, seal, and burst testing of your packages for total package integrity Package leak detectors ensure that seal integrity problems are identified. This is a vital part of Modified Atmosphere Packaging (MAP) quality control, since compromising the protective atmosphere will cause a reduction in the shelf-life of MAP products . If your car has a vacuum leak, there is a good chance someone already had the same problem in the same car. Try, for example, searching YouTube or Google for 'Toyota Corolla 2005 common vacuum leak' and you will see people posting the repair information. In this car (Corolla), the intake manifold is the common source of vacuum leaks. We also .

Cincinnati Test Systems is a leading manufacturer of leak detection, verification test units and leak test systems for all industries. Contact us today 513-367-6699

A wet vacuum package test is simply a bubble leak test on your sachet bags by placing them inside a water filled vacuum chamber and pulling a vacuum. We have a more in-depth write up on the bubble leak test here: (Bubble Leak Testing using an Acrylic Vacuum Chamber), but if you are new to this, let’s keep going.

Here's how you can test and ensure there are no vacuum leaks in your car engine. . Wherever it exits the system is the cause of your leak. A smoke machine is an invaluable tool that makes diagnosis much easier. 3. Use A Flammable Spray Carefully . The intake manifold gasket is the seal that is found between the cylinder head and the intake . Learn how to use a smoke machine for detecting vacuum leaks that can harm your engine's performance and fuel efficiency. This guide walks you through identifying common leak sources, setting up the machine, and analyzing smoke patterns to pinpoint issues in intake manifolds, throttle bodies, and vacuum hoses. By following our detailed steps, you’ll ensure . Discover how to build your own smoke machine for detecting vacuum leaks that can affect engine performance and fuel efficiency. This article provides a comprehensive, step-by-step guide using simple materials like fog juice, a plastic bottle, and a heating element. Learn essential safety tips and effective usage techniques while ensuring optimal system .

Vacuum and Pressure decay leak testing Venice, 22. March 2019 Presenter: Dr. Matthias Kahl, Head of R&D WILCO AG, CH. 2 . –LFC, P, V (different types) –pressure curve / course –steps of the differential pressure test • Method selection • Equipment in process control • Applications of differential pressure . sealing. 14 LFC .of automatic leak testing machines & leak test systems for assembly lines or laboratories. FOR YOUR TESTING NEEDS! 49 years after its creation, ATEQ is now a 187 M€ company with offices in 40 countries selling and servicing more .

vacuum leak test procedure

The vacuum decay leak testing technique is ideal for non-porous flexible packages, rigid and semi-rigid packaging, and rigid, non-porous containers. Ascend offers multi-functional non-destructive leak testing .

Learn how to check for intake manifold vacuum leaks and enhance your engine's performance. This comprehensive article covers symptoms, diagnostic methods, and essential tools like a vacuum gauge and smoke machine. Discover effective techniques, including visual inspections and smoke testing, to identify leaks and ensure proper connections. Stay ahead .The Presto leak detector machine is a high quality packaging seal integrity tester that adds quality control measures to your packaging applications. Regardless of contents, the vacuum seal integrity test will help ensure that your packaged product is sealed to your specifications. Benefits of will be realized by many industries from package .Vacuum leak testing is the principal leak test method for testing sealed parts that could have leakage from an external source into their housings and casings. Prime tests for vacuum leak test procedures include: Underwater sensors or housings; Outdoor electrical housings; Sealed components; Components associated with vacuum sources

Welcome to Seal-Check.Pro, the premier provider of high-quality package leak detection systems, where innovation meets reliability.Our state-of-the-art vacuum leak testers are meticulously crafted to ensure the utmost integrity of your packaging, making us the go-to choice for industries ranging from food packaging to pharmaceuticals.C660M Leak and Seal Strength Tester. C660M Leak and Seal Strength Tester can used for leak test, burst test and creep test of finished packages and three-side sealed packages, based on ISO 11067, ASTM F1140 & ASTM F2054.

In line with the FDA approved ASTM F2338-09 standard test method and USP 1207 guidelines, the Multi-Q with vacuum decay method is developed to detect leaks in vials, ampoules, bottles, pre-filled syringes, blow fill seal strips, medical devices, trays and other containers containing water-based liquid, down to 5μm*.Operating the RECON 1500 Tube Leak Test Gun is simple. With the air supply connected, plug one tube end with the test gun and the other end with the T-Handle Plugging Tool. Press the lever trigger and the Venturi System quickly and efficiently evacuates the tube. Then monitor the gauge for loss of vacuum, which indicates a tube leak.Utilize the RECON Series tube leak test guns and test every tube quickly and efficiently with the most ergonomic test gun on the market. . Vacuum Test Gun. Find Tube Leaks Quickly & Easily. . Tapered seal design allows the operator to test a large range of tube IDs without changing seals, washers, or support tube assemblies. .The PRESTO® leak detector is a seal integrity testing system which can be used for various testing methods to determine whether there is some fault with the tested product in case there is a faulty seal. Our leak detection tester can be used to test for all types of packages which can vary from: Bubble Emission tests, to Vacuum Package tests .

Based in Nottingham, UK, TQC design and develop leak testing equipment for manufacturing sectors around the world. Casting Leak Testing Engine Block Testing Helium Leak Test Facility. A niche area of engineering, leak testing is sometimes referred to as pressure testing or vacuum testing. TQC has the knowledge and expertise to assist the .

hardness test for steel

vacuum leak detection methods

WEBLoterias | CAIXA

vacuum seal leak testing machine|vacuum leak testing methods